products

- home

- Products

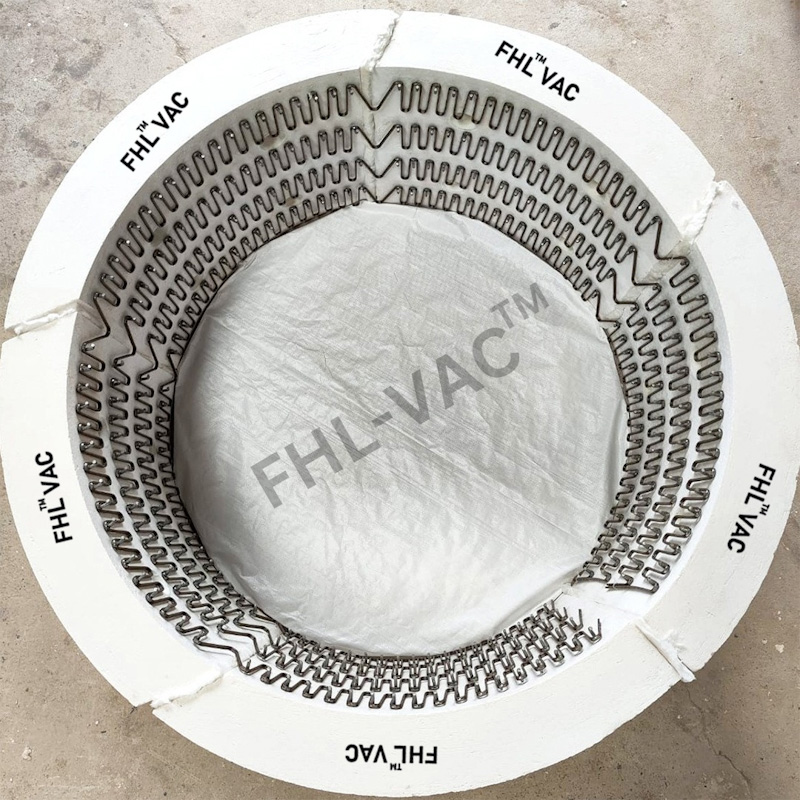

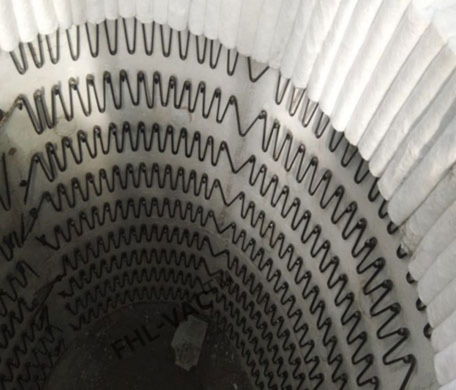

FHL-VACTM Free Radiating Cylindrical Insulation Segment With Heating System

FHL-VACTM Free Radiating Cylindrical Insulation

Segments are another special type of panels where heating element is hung at

the surface of insulating module which radiate thermal energy into the

required chamber, meanwhile ceramic panel resist energy loss to atmosphere.

We manufacture the following product in various size and grade to meet our

customer needs.

Custom Built Board Dimensions:

• Thickness: 90, 100, 125mm

• From ID: 150mm up to Customer Requirement

• We work for your exacting requirements

Type of Heater Used:

• FHL - Single Core ROB Heaters

• FHL - Multicore ROB Heaters

• FHL - SOB Heaters

Application:

• Pit Furnace

• Bell Furnace

• Split Furnace

Technical Data of FHL-VAC ™ Vacuum Formed Ceramic Fiber Modules & Panels

| Parameter | FHL-M 1150 | FHL-Z 1325 | FHL- HT 1550 |

|---|---|---|---|

| Classification Temp (°C) | 1260 | 1425 | 1650 |

| Max. Continuous Working Temp. (°C) | 1150 | 1325 | 1550 |

| Density Range (Kg/m3) | 200-240 | 200-240 | 200-240 |

| Linear Shrinkage (%) (24 Hour Continuous Working Temp.) | 1< | 1< | 1< |

Thermal Conductivity (W/mK)

| Parameter | FHL-M 1150 | FHL-Z 1325 | FHL- HT 1550 |

|---|---|---|---|

| At 200°C | 0.065 | 0.065 | 0.065 |

| At 600°C | 0.13 | 0.13 | 0.14 |

| At 1000°C | 0.27 | 0.28 | 0.24 |

| At 1200°C | 0.40 | 0.38 | 0.33 |

| At 1300°C | 0.48 | 0.47 | 0.39 |

| At 1400°C | - | 0.53 | 0.45 |

| At 1500°C | - | - | 0.51 |

| At 1600°C | - | - | - |

Chemical Composition (%)

| Parameter | FHL-M 1150 | FHL-Z 1325 | FHL- HT 1550 |

|---|---|---|---|

| Al2O3 | 47 | 37.5 | 66 |

| SiO2 | 53 | 49.5 | 33 |

| Zr | - | 13 | - |

Technical Data Sheet of FHL-Heating Alloys

| Fe-Cr-Al Heating Element Alloy 1 Alloy 2 |

Ni-Cr 80 Heating Element | ||

|---|---|---|---|

| Standard Chemical Composition (%) | Al 6.0 | Al 6.0 | Cr 19-21 |

| Cr 23 | Cr 23 | Fe < 1 | |

| Fe 71 | Fe 70 | Ni 77 or more | |

| Other Elements in Small Quantity | |||

| Max. Duty Temp. of Heating Element (°C) | 1400 | 1420 | 1100 |

| Electric Resistivity (Ω mm2 m-1) | 1.45 ± 5% | 1.45 ± 5% | 1.08 ± 5% |

| Expansion from Thermal Factor | 15.1 x 10-6 | 14.8 x 10-6 | 17.6 x 10-6 |

| Hardness Hv Melting Point (°C) |

200-240 1500 |

200-240 1500 |

200-190 1500 |

| Electric Resistance Temp. Coefficient | 33 x 10-6 | 15 x 10-6 | 58 x 10-6 |

| Increase from Oxidation 1200°C (mg/cm2h) | 0.05 | 0.05 | 0.25 or less |

| Tensile Strength MPa (Kgf/mm2) |

650-900 (65-90) |

650-900 (65-90) |

700-900 (70-90) |

| Specific Gravity Elongation (%) |

7.1 15-25 |

7.1 15-25 |

8.4 20 or more |