products

- home

- Products

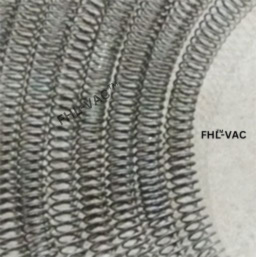

FHLTM SPIRAL HEATING ELEMENT

Our Specializations :

• Spiral Heating Element with any wire diameter and size

• We can also work for your exacting requirements

Advantages:

• Can be used for heating tubing systems.

• Used in grooved refractories.

• Used for coil on tube heaters/candy heaters.

Technical Data Sheet of FHL-MulticoreTM Heating Alloys

| Fe-Cr-Al Heating Element Alloy 1 Alloy 2 |

Ni-Cr 80 Heating Element | ||

|---|---|---|---|

| Standard Chemical Composition (%) | Al 6.0 | Al 6.0 | Cr 19-21 |

| Cr 23 | Cr 23 | Fe < 1 | |

| Fe 71 | Fe 70 | Ni 77 or more | |

| Other Elements in Small Quantity | |||

| Max. Duty Temp. of Heating Element (°C) | 1400 | 1420 | 1100 |

| Electric Resistivity (Ω mm2 m-1) | 1.45 ± 5% | 1.45 ± 5% | 1.08 ± 5% |

| Expansion from Thermal Factor | 15.1 x 10-6 | 14.8 x 10-6 | 17.6 x 10-6 |

| Hardness Hv Melting Point (°C) |

200-240 1500 |

200-240 1500 |

200-190 1500 |

| Electric Resistance Temp. Coefficient | 33 x 10-6 | 15 x 10-6 | 58 x 10-6 |

| Increase from Oxidation 1200°C (mg/cm2h) | 0.05 | 0.05 | 0.25 or less |

| Tensile Strength MPa (Kgf/mm2) |

650-900 (65-90) |

650-900 (65-90) |

700-900 (70-90) |

| Specific Gravity Elongation (%) |

7.1 15-25 |

7.1 15-25 |

8.4 20 or more |